Water jet cutting is an alternative to other cutting methods, such as laser cutting and plasma arc cutting. The main application of water jet cutting in medical technology is for making orthopedic implants, surgical guides, surgical instruments, and prosthetics.

What Is Water Jet Cutting?

Water jet cutting is a form of precision machining that uses a high-pressure stream of water to cut through metal and other materials. While laser cutting involves intense heat, waterjet cutting uses only compressed air and water. Water jet cutting is often used as an alternative to laser cutting since it can achieve similar results but at a lower cost.

A precision waterjet cutting tool uses high-pressure water to cut materials. The water is pressurized up to 100,000 psi (pounds per square inch) and flows through a nozzle at speeds of up to 2,000 mph. A computer controls the pressure and speed of the water flow so that it can easily cut through tough metals.

The process begins when you place your material into the machine’s “work envelope” (the area where it will be able to move around), then run your design file through CAM software to create tool paths for each layer of material you want to be removed. These tool paths are then translated into instructions that tell the computerized cutter where to go and what kind of cuts need to be made on each layer.

Once this step is complete, all you need do is press start and watch as your custom piece comes together before your eyes.

Uses Of Water Jet Cutting Technology In Medicine

Water jet cutting can be used in a variety of industries, including medical technology. Water jet cutting has many applications in medical technology, especially when precision and accuracy are needed. Water jet cutting is used for implantable devices such as orthotics and prosthetics, surgical guides, and other medical components.

Here are some more detailed uses of water jet cutting in medical technology:

1. Implantable Devices

Water jet cutting can be used to make implantable devices. Implantable devices are small, precise, and have a wide range of applications in the medical field.

Water jet cutting is an efficient method for manufacturing such devices because it can cut through metal with high precision and at a very low cost per unit. It’s also possible to use water jet cutting to make devices that are not implantable, such as jewelry.

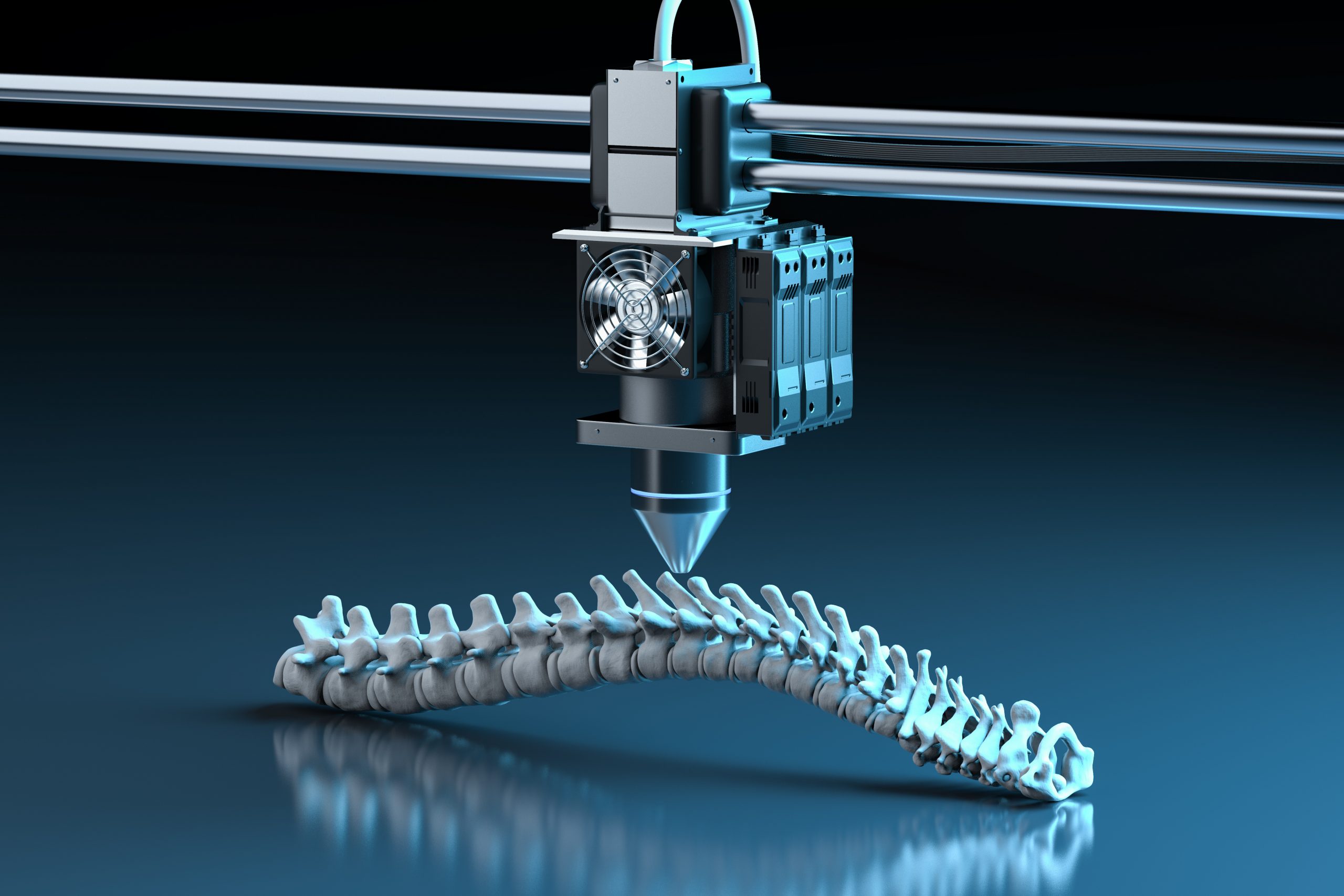

2. Surgical Guides

Water jet cutting is used to make surgical guides for orthopedic, dental, and spinal surgery. The process starts with a CT scan or MRI of the patient’s bone. The doctor uses software to create a 3D image of the bone and surrounding tissue. This image can be printed on a 3D printer in plastic or metal, creating a guide that shows where the surgeon should cut during an operation.

The guide is attached to the patient’s bone and helps surgeons cut precisely. It also prevents them from cutting any important nerves or blood vessels during surgery.

3. Orthotics And Prosthetics

Orthotics and prosthetics are medical tools used to restore mobility, balance, and function to people with disabilities. Water jet cutting is one of the most popular methods used to fabricate such devices.

This method can be used to create custom-fit orthotics and prosthetics made of plastic, metal, or composite materials. There’s a range of cutting systems designed to meet specific needs. Each of these systems can produce high-quality orthotics and prosthetics that people with disabilities can use.

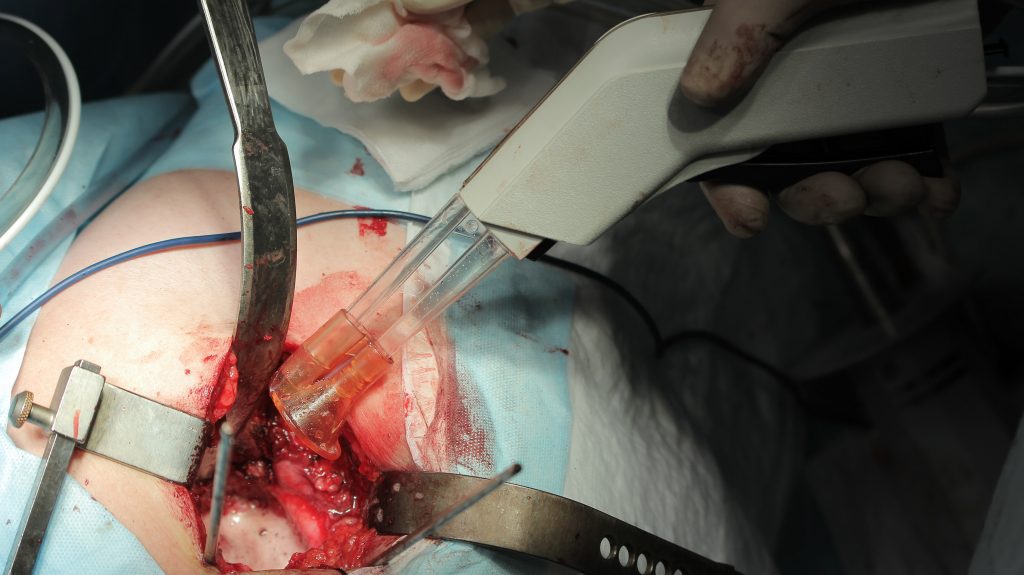

4. Surgical Instruments

Water jet cutting is used to create surgical instruments used in minimally invasive surgery. Water jets also cut through materials such as rubber, foam, and even human skin. In addition, parts of the body can be cut using a water jet. For example, an incision may be made on a patient’s abdomen during laparoscopic surgery using a water jet so that surgeons can operate inside the body without making any large openings in the skin.

Water jet cutting has many benefits over other types of cutting. For example, it can be used to cut through materials that are not easily cut using traditional methods. In addition, water jets can cut through materials quickly and with minimal effort on the operator’s part.

Summary

A water jet is a cutting tool that uses high-pressure water to cut or carve through materials. A typical jet consists of a nozzle, which sprays the water at high pressure and velocity, along with an air compressor that supplies air to keep the nozzle stable as it cuts through whatever material you are working on.

Water jet cutting is a great technology for medical applications because it offers precision and accuracy, which are important in medical technology.